Application of CNC EDM machines in the mold industry

Spark machines are often used to process molds and mechanical products that require high precision, difficult profiles, and high rigidity for which machining on conventional machine tools is not efficient or impossible. meetable.

EDM technology is also used in the making of blow molds. Blow molds are used to produce complex shaped plastic products, such as plastic bottles, liquid containers, air pipes, water pipes, nozzles and others. Applications of EDM in blow mold manufacturing include the fabrication of blow molds for the food, medical, electronics and other industries. EDM technology is also used in making plastic injection molds. Plastic injection molds are used to produce high precision and complex shaped plastic products, such as phone cases, keyboards, phone cases, air ducts, water pipes, nozzles and other products. other products. EDM technology is used to make punching molds with difficult shapes. It has the advantage of being able to process hard and non-deformable materials EDM machining is a machining method involved in the manufacturing of pressure casting molds. CNC milling is used to create the basic parts of the mold, while the EDM machine is used to machine the remaining difficult parts of the mold. CNC-EDM can create parts with high precision and high durability. It allows the production of molds with complex shapes and small parts accurately and quickly.

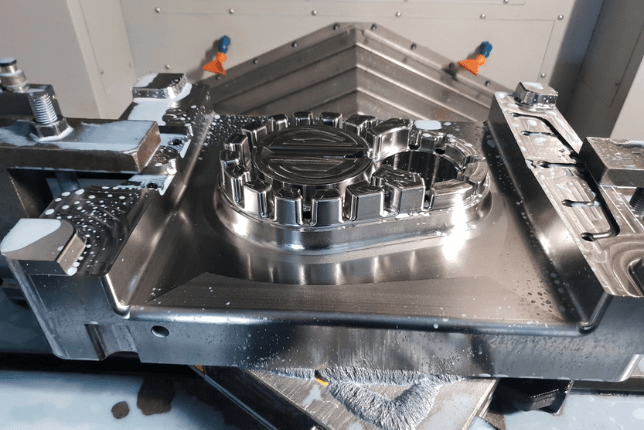

Blow Mold

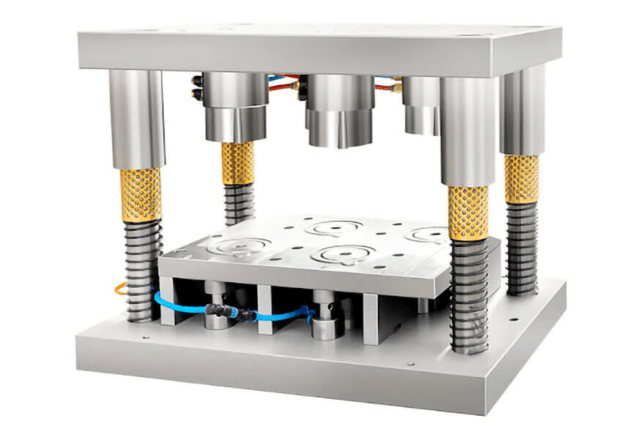

Plastic injection mold

Applications of EDM in plastic injection mold making include making plastic injection molds for electronic, automotive, medical and other consumer products.

Punching Mold

Pressure Die Casting